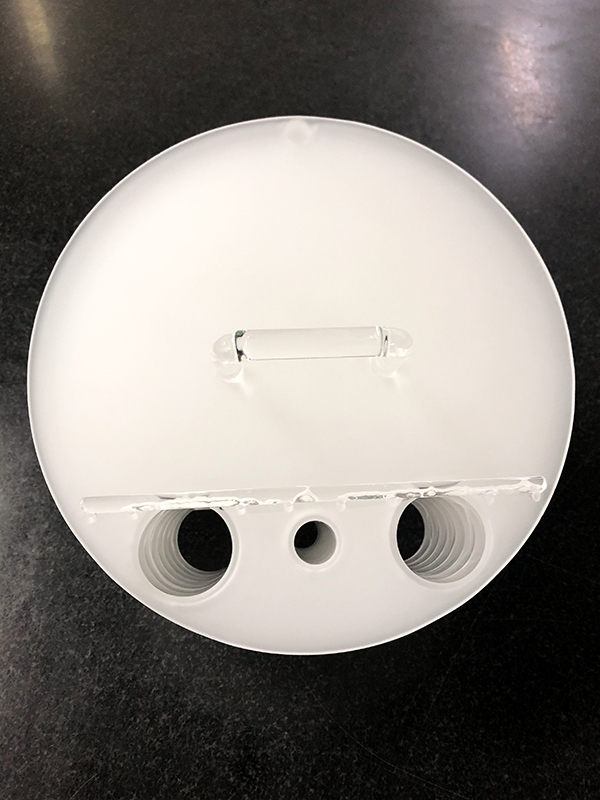

Quartz Cap

Name:

8-inch Quartz Cap (Quartz Inner Plug)

Function & Application:

The quartz cap is a sealing element of the quartz tube that effectively controls the stability of furnace temperature during wafer processing and reduces heat radiation loss. It is applied in diffusion, oxidation, and CVD deposition processes in wafer manufacturing, which are high-temperature processes.

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, sandblasted surface treatment, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

The fused silica caps are precision-made components designed to seal and protect quartz tubes, reactors, and wafer boats during high-temperature semiconductor and photovoltaic processing. Crafted from ultra-pure fused silica, these caps offer exceptional thermal shock resistance, chemical inertness, and durability under repeated thermal cycling.

Their tight sealing capability prevents contamination and gas leakage, ensuring a stable and clean processing environment essential for oxidation, diffusion, LPCVD, and annealing processes. The caps’ robust construction helps maintain process consistency and extends equipment lifespan in demanding manufacturing settings.

Integration of Fused Silica Caps with Vertical and Horizontal Semiconductor Furnaces

Compatibility with Vertical and Horizontal Furnaces

Furnaces come in different orientations, and the design of fused silica caps must match the specific system. Vertical furnaces benefit from caps that maintain uniform gas flow along the vertical axis, while horizontal furnaces require caps optimized to prevent localized heating and ensure even exposure across all wafers.

Thermal and Chemical Stability

High-purity fused silica caps resist thermal shock and chemical attack, making them ideal for processes like diffusion, oxidation, and CVD deposition. Their ability to withstand high temperatures without deformation ensures stable furnace operation and protects delicate wafers during batch processing.

Optimizing Gas Flow and Process Efficiency

The integration of fused silica caps with furnace systems directly affects gas distribution. Properly designed caps guide process gases evenly, reduce turbulence, and minimize particle contamination. This contributes to more uniform film deposition and improved device performance.

Installation Considerations

When installing fused silica caps, attention to alignment, fit, and surface cleanliness is crucial. Misaligned caps can disrupt gas flow and create temperature gradients, negatively impacting wafer uniformity. Using compatible fixtures and handling tools helps maintain the integrity of both the cap and the furnace.