NEWS DETAIL

Quartz parts play an essential role in semiconductor manufacturing, especially in high-temperature, high-purity environments. But when it comes to selecting the right component—particularly between a quartz base (also known as a quartz pedestal) and a quartz plate—the differences may not be immediately clear. Though both are made from high-purity fused silica, their purposes, structures, and pricing can vary significantly.

In this article, DKEQ breaks down the key distinctions between quartz bases and quartz plates, helping you choose the right solution for your equipment and process needs.

What are Quartz Bases and Quartz Plates?

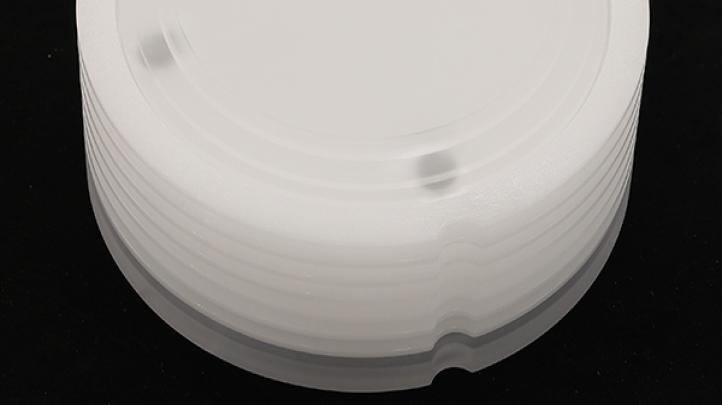

A quartz base, also referred to as a quartz pedestal, is a precision-machined component typically used as a support platform in semiconductor equipment. It may feature custom shapes, slots, holes, or steps to hold wafers, carriers, or reaction parts during high-temperature processes such as diffusion, CVD, or ion implantation.

In contrast, a quartz plate is generally a flat sheet of fused quartz, available in standard sizes and thicknesses. It may be used as a viewing window, spacer, cover, or thermal insulator. Quartz plates are simpler in shape and often serve more general purposes.

Key Differences Between Quartz Bases and Quartz Plates

| Feature | Quartz Base / Pedestal | Quartz Plate |

| Function | Supports wafers or process modules | Serves as a flat cover, insulator, or substrate |

| Structure | 3D, often with holes, grooves, or slots | Flat, usually rectangular or circular |

| Customization | Highly customized per machine design | Often standard, but cutting available |

| Use Case | Diffusion furnaces, CVD chambers | Viewports, insulators, shielding plates |

| Processing Method | CNC machining, polishing, annealing | Cutting, edge grinding, surface polishing |

Quartz bases are typically load-bearing or position-critical parts that must meet tight tolerances and specific designs. Quartz plates are more universal and easier to fabricate, with less structural complexity.

Which One is Better for Semiconductor Equipment?

It depends entirely on the role the part is playing in your system.

If your application involves supporting wafers, guiding process gases, or positioning substrates inside a high-temperature furnace, a quartz base/pedestal is usually the right choice.

If you need a protective cover, window, or flat spacer, a quartz plate may be more appropriate—and more cost-effective.

In most semiconductor tools, both types of quartz parts are used in combination. The key is selecting the right part for the right purpose.

Which One Costs More — Quartz Plate or Base?

Generally speaking, a quartz base costs more than a quartz plate due to:

a. Higher complexity in design

b. Multi-step machining and polishing

c. Tight tolerance requirements

d. Often made-to-order for specific tool models

Quartz plates, being flat and simpler to cut and polish, are more economical, especially when purchased in standard sizes. However, if a quartz plate requires edge machining, holes, or thermal treatment, its cost can rise significantly as well.

Is Customization Available for Both?

Yes—but with different expectations.

At DKEQ, we provide customization services for both quartz bases and plates, including:

For Quartz Bases: Custom dimensions, slots, stepped designs, drilled holes, and assembly with other materials (e.g., silicon carbide inserts)

For Quartz Plates: Custom cutting, polishing, edge beveling, and drilled holes

While quartz plates offer faster turnaround for standard cuts, quartz bases usually require engineering drawings and may involve longer lead times due to the complex fabrication process.

Both quartz bases and quartz plates serve important roles in semiconductor manufacturing, but they are designed for very different tasks. Choosing the right one depends on your process requirements, equipment design, and budget.

If you’re still unsure, DKEQ’s technical team is ready to help evaluate your application and recommend the most suitable solution—whether that’s a custom-machined quartz pedestal or a standard quartz plate.