NEWS DETAIL

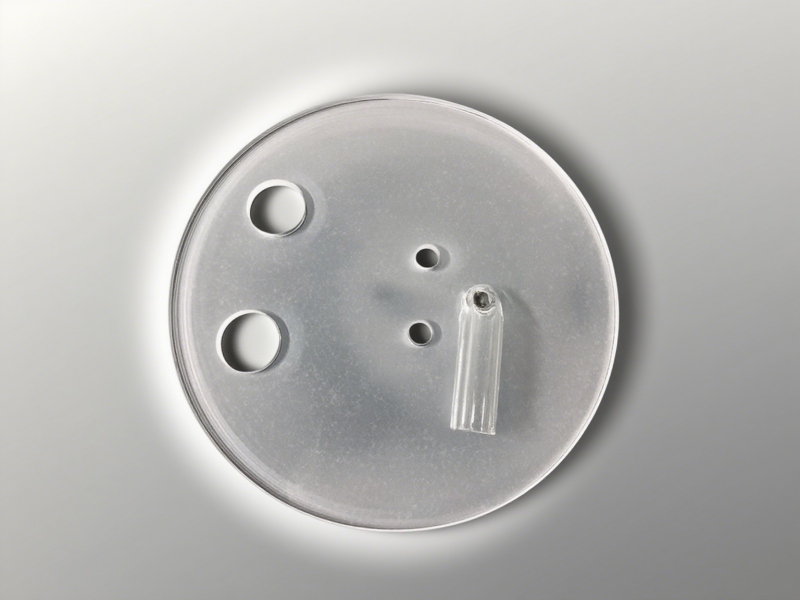

Quartz caps are specialized components crafted from synthetic or natural quartz crystal. Unlike ordinary glass, quartz boasts exceptional thermal, chemical, and mechanical properties. These caps typically serve as protective covers or sealing elements for devices exposed to high temperatures, corrosive chemicals, or ultraviolet light. Their transparency to UV and infrared light makes them indispensable in optics and photonics applications. While the concept sounds technical, quartz caps are essentially robust shields designed to maintain the integrity and functionality of sensitive equipment.

Features of Quartz Caps

Quartz caps come with a range of standout features that make them ideal for demanding environments:

- Exceptional Thermal Resistance: Quartz can withstand temperatures up to about 1200°C without melting or deforming, far beyond typical glass limits.

- High Chemical Stability: Resistant to most acids, alkalis, and solvents, quartz caps maintain structural integrity even in harsh chemical settings.

- Optical Transparency: Offering excellent transmission of ultraviolet (UV), visible, and infrared (IR) light, quartz caps enable precise optical measurements and processes.

- Low Thermal Expansion: Quartz expands very little under heat, minimizing stress and cracking risks during rapid temperature changes.

- Mechanical Strength: Despite their fragile appearance, quartz caps resist mechanical stress better than many other materials used in similar roles.

- Purity and Cleanliness: High-purity quartz reduces contamination risks in sensitive environments such as semiconductor fabs or pharmaceutical labs.

Why Choose Quartz Caps Over Other Materials?

When considering protection or sealing solutions, quartz caps stand out due to several clear advantages:

- Superior Temperature Handling: Unlike ordinary glass or plastic caps, quartz withstands extreme heat without losing shape or clarity, essential for furnace covers or high-temperature reactors.

- Chemical Resistance: Many metals or polymers corrode or degrade under exposure to acids or solvents; quartz remains inert, ensuring longer lifespan and reliability.

- Optical Clarity: For optical devices, quartz caps don’t interfere with light transmission, unlike some plastics that may absorb or distort wavelengths.

- Long-Term Stability: Quartz doesn’t yellow or degrade under UV exposure, making it preferable in outdoor or high-UV environments.

- Minimal Maintenance Needs: Quartz caps rarely require frequent replacement due to their durability, lowering operational downtime and costs.

While alternatives such as borosilicate glass or sapphire may be used, quartz offers a unique combination of affordability, purity, and performance tailored to high-tech industries.

Maintenance Tips for Quartz Caps

Proper care helps maximize the service life of quartz caps, preserving their functionality and appearance:

- Gentle Cleaning: Use mild detergents and soft cloths or brushes to remove dust or residue. Avoid abrasive materials that can scratch the surface.

- Avoid Thermal Shock: Prevent rapid temperature changes; preheat or cool quartz caps gradually to reduce cracking risk.

- Handle with Care: Although strong, quartz caps can chip or break from impact, so handle them with appropriate protective gear and storage methods.

- Inspect Regularly: Check for any micro-cracks, discoloration, or surface damage that might affect performance, especially in optical applications.

- Avoid Harsh Chemicals: While quartz is chemically resistant, avoid strong mechanical scrubbing with acids or bases that could eventually etch the surface.

Following these tips ensures that quartz caps remain clear, strong, and effective for extended periods.

FAQs from Buyers

Q: Can quartz caps be custom-made to fit specific equipment?

A: Absolutely. Many manufacturers offer customization in size, thickness, and shape to match precise application needs.

Q: Are quartz caps fragile and prone to breaking?

A: While quartz is harder and more heat-resistant than ordinary glass, it still requires careful handling to avoid chips or cracks.

Q: What industries commonly use quartz caps?

A: Semiconductors, photovoltaics, laboratory instruments, lighting, and chemical processing frequently rely on quartz caps for reliable performance.

Q: How do quartz caps compare cost-wise to other materials?

A: Although quartz caps may cost more upfront than plastic or glass alternatives, their durability and performance often justify the investment.

Q: Is it safe to use quartz caps with food or pharmaceutical products?

A: Yes, due to their purity and chemical inertness, quartz caps are safe and widely used in pharmaceutical and food-grade applications.

Quartz caps may not be the most glamorous components, but their role is vital in countless high-tech processes. Their unique combination of heat resistance, chemical inertness, and optical clarity makes them a smart choice for anyone seeking reliability and performance in demanding environments.