NEWS DETAIL

Quartz showerheads, though often overlooked, play a critical role in ensuring uniform coating and etching across wafers. Having worked in the quartz components industry for over a decade, I can confidently say that selecting the right showerhead can significantly influence process stability, product yield, and long-term equipment performance.

What is a Quartz Showerhead?

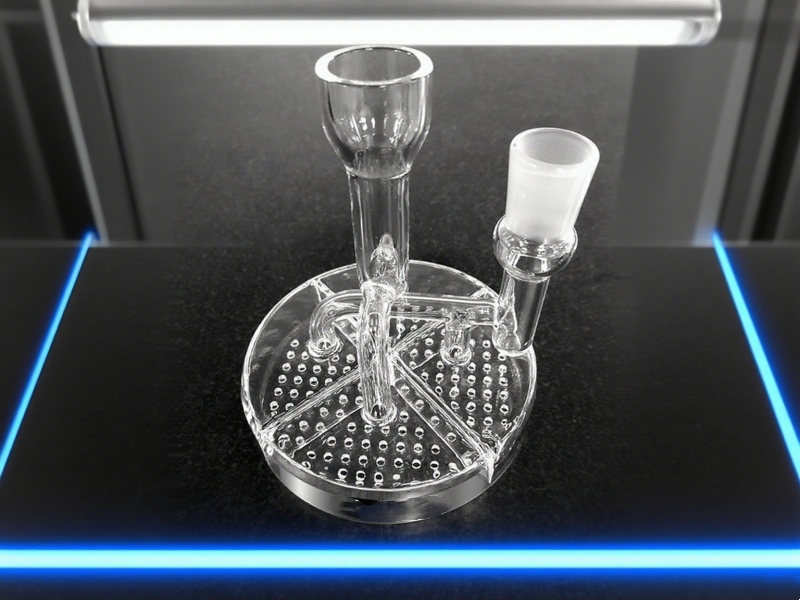

A quartz showerhead is a precision-engineered component installed inside the reaction chamber of PVD, CVD, PECVD, and etching equipment. Its surface is perforated with numerous fine holes designed to evenly spray specialty process gases over the entire wafer. This ensures consistent deposition or etching across the wafer, minimizing thickness variations and improving process reproducibility. In essence, the showerhead acts as the “gas distributor” that directly impacts film uniformity and quality.

Key Highlights and Advantages

Uniform Gas Distribution

Why it matters: Uneven gas flow can create non-uniform films, causing defects and reducing wafer yield.

Quartz showerhead advantage: The finely perforated design guarantees that gases are sprayed evenly, covering every part of the wafer.

From my experience, proper gas distribution is often the single most critical factor in achieving consistent results in high-temperature deposition or etching processes.

High Temperature Resistance

Why it matters: PVD, CVD, PECVD, and etching processes operate at elevated temperatures. Components that cannot withstand these conditions may warp or degrade, affecting wafer quality.

Quartz showerhead advantage: Made of high-purity quartz with excellent thermal stability, these showerheads maintain their shape and performance even under prolonged high-temperature operation.

Corrosion Resistance

Why it matters: Process gases can be highly reactive, potentially corroding standard materials and introducing impurities.

Quartz showerhead advantage: Quartz inherently resists corrosion, preserving the chemical integrity of gases and preventing contamination.

My recommendation for fabrication engineers is to always verify material compatibility with reactive gases to ensure long-term stability.

Low Impurity Content

Why it matters: Contaminants in showerhead material can deposit onto wafers, causing defects and reducing device performance.

Quartz showerhead advantage: High-quality quartz showerheads feature extremely low impurity content, helping maintain wafer purity and yield consistency.

This is a crucial consideration in advanced semiconductor manufacturing where even trace impurities can have significant effects.

Optimized Surface Treatment

Why it matters: Surface roughness can affect gas flow patterns and uniformity.

Quartz showerhead advantage: Sandblasted or specially treated surfaces ensure smoother gas distribution and reduce localized turbulence.

Based on my experience, this seemingly minor detail can noticeably improve film uniformity, particularly in large-diameter wafers.

Practical Recommendations

1. Process engineers should always match showerhead specifications with their chamber design and gas chemistry to achieve optimal results.

2. Maintenance teams should periodically inspect for surface wear or clogging of perforations to maintain uniform gas distribution.

3. Procurement specialists should prioritize high-purity quartz and verified thermal and chemical resistance to ensure long-term stability.

A quartz showerhead is not just a passive component; it is central to achieving uniform, high-quality wafer processing. Its precise design, thermal resilience, corrosion resistance, and low impurity content make it an indispensable element in advanced semiconductor manufacturing. Selecting the right showerhead, coupled with proper maintenance and process optimization, can significantly improve yield and process consistency—a fact I have observed repeatedly in my years within the quartz industry.