NEWS DETAIL

Why Quartz is Indispensable in Semiconductor Manufacturing

The Role of Quartz for Semiconductor

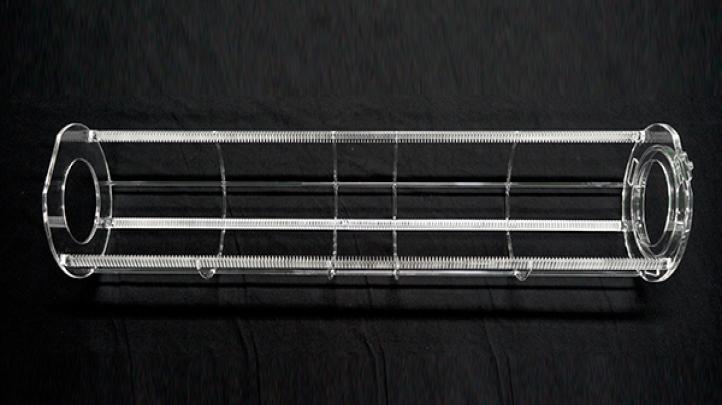

Quartz plays an essential role in semiconductor manufacturing due to its unmatched combination of purity, durability, and stability under extreme conditions. In the complex processes of wafer fabrication—such as oxidation, diffusion, deposition, and etching—quartz is the go-to material for making tubes, boats, crucibles, and other precision components that directly contact silicon wafers.

The high purity of quartz prevents contamination, which is critical since even microscopic impurities can damage chips or alter their electrical properties. Moreover, its excellent resistance to thermal shock allows quartz to endure the drastic temperature changes common in semiconductor furnaces. From wafer processing to inspection systems, quartz components ensure that every stage maintains the precision and cleanliness the industry demands.

What Makes Quartz So Special?

What sets quartz apart is its unique combination of physical, chemical, and optical properties. As a naturally abundant mineral composed mainly of silicon dioxide (SiO₂), quartz can be refined into extremely high-purity forms—often reaching 99.999% or higher. This purity ensures no interference with the microelectronic structures on semiconductor wafers.

Additionally, quartz exhibits low thermal expansion and high thermal resistance, which minimizes deformation during rapid heating and cooling cycles. Its chemical inertness ensures that it does not react with the gases or chemicals used in deposition and etching. Furthermore, quartz’s optical transparency to UV and infrared light enables its use in photolithography and cleaning applications, where precise energy transmission is essential.

In short, quartz combines heat stability, chemical resistance, and purity—qualities that are difficult to find in any single alternative material.

Advantages of Quartz over Alternative Materials

Compared with ceramics, glass, or metals, quartz offers several distinct advantages that make it indispensable in semiconductor production.

- Purity and Cleanliness: While ceramics may contain impurities and metals can introduce contamination, quartz remains chemically stable and non-reactive.

- Thermal Stability: Glass softens at lower temperatures, but quartz retains its shape and strength even above 1000°C.

- Dimensional Precision: Quartz’s low thermal expansion rate ensures consistent component dimensions, reducing the risk of wafer misalignment or thermal stress.

- Transparency: Unlike opaque materials, quartz allows precise UV transmission, which is vital in photolithography and optical applications.

These advantages make quartz not only a preferred choice but often the only viable option for high-precision semiconductor environments where reliability and cleanliness are non-negotiable.

Future of Quartz in the Semiconductor Industry

As semiconductor technologies advance toward smaller nodes and more complex architectures, the demand for ultra-pure, high-performance materials continues to grow. Quartz will remain a cornerstone of this evolution. Manufacturers are investing in developing synthetic quartz with even higher purity and improved structural uniformity to meet next-generation requirements.

Moreover, innovations in quartz machining and surface treatment are improving precision and reducing micro-contamination risks. As chip production shifts toward advanced processes like EUV lithography and 3D chip stacking, quartz’s optical and thermal properties will become even more crucial. In essence, the future of semiconductors and the future of quartz are deeply intertwined.

Quartz has proven to be more than just a supporting material—it is a foundation of semiconductor manufacturing. Its unique combination of purity, durability, and stability under high temperatures ensures consistent performance across all fabrication stages. With continuous technological advancements, quartz will remain indispensable in enabling cleaner, faster, and more efficient semiconductor production.