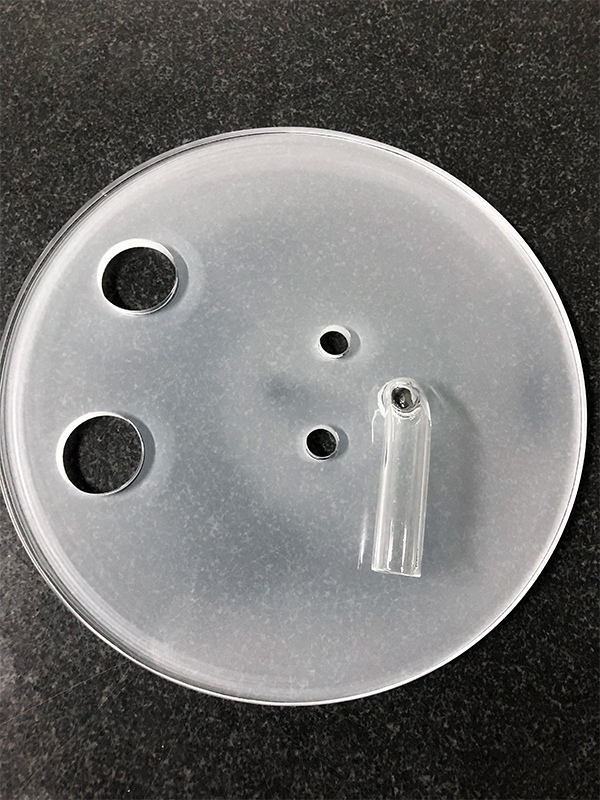

Quartz Baffle

Name:

6-inch Quartz Baffle

Function & Application:

The frosted baffle provides thermal insulation for the high-temperature processing furnace tube. Small tubes on the baffle allow the injection of gases required for wafer manufacturing. It is applied in diffusion, oxidation, and CVD deposition processes in wafer manufacturing, which are high-temperature processes.

Performance Requirements:

High temperature resistance, corrosion resistance, excellent thermal stability, sandblasted surface treatment, and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

The Quartz Baffle features a frosted, sandblasted surface designed to provide effective thermal insulation within high-temperature semiconductor furnace tubes. Its structure incorporates small tubes to facilitate precise injection of process gases necessary for wafer manufacturing, such as diffusion, oxidation, and CVD deposition.

Constructed from high-purity fused quartz, this baffle offers excellent resistance to heat, chemical corrosion, and thermal shock, while maintaining low impurity levels to minimize contamination risks. The sandblasted surface enhances thermal performance and reduces particle generation, ensuring stable temperature control and consistent gas distribution throughout the process. Ideal for semiconductor fabs and R&D labs, the Quartz Baffle improves process uniformity and wafer quality.

How Quartz Baffles Improve Wafer Uniformity and Yield

1. Ensuring Uniform Gas Flow

Quartz baffles guide process gases evenly across all wafers. By preventing localized gas turbulence, they help maintain consistent chemical reactions and layer deposition, which reduces wafer-to-wafer variation.

2. Thermal Distribution Control

Baffles reflect and diffuse thermal energy, minimizing hot spots and direct radiation on wafer surfaces. This uniform temperature distribution ensures precise diffusion, oxidation, and deposition processes, protecting wafers from thermal stress.

3. Contamination Prevention

The precise design of quartz baffles reduces particle generation and backstreaming of process byproducts. Cleaner processing environments contribute to higher yields and lower defect rates.

4. Compatibility with Automated Systems

High-quality quartz baffles are manufactured to tight tolerances, ensuring proper alignment and integration with wafer carriers and automated handling systems, maintaining process reliability and repeatability.

By optimizing gas flow and thermal uniformity while minimizing contamination risks, quartz baffles play a key role in improving wafer uniformity and enhancing semiconductor production yields.