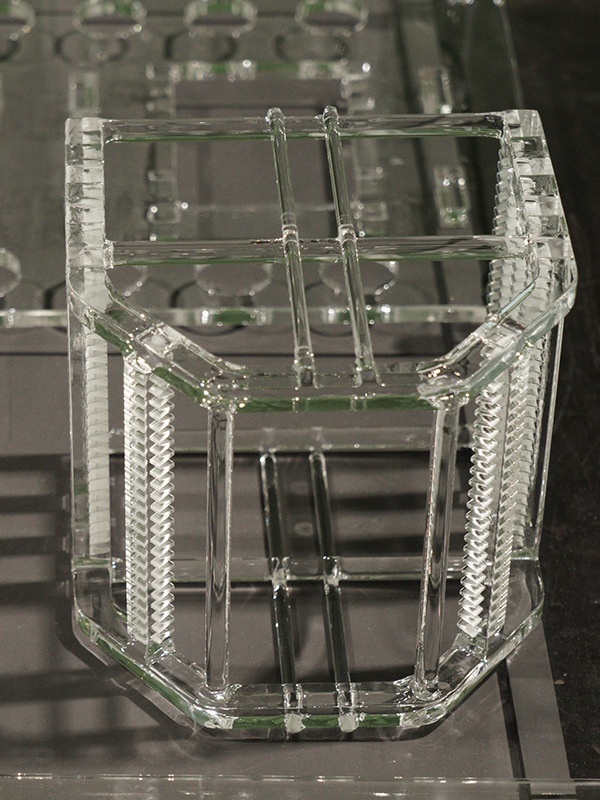

Quartz Boat

Name:

6-inch Quartz Boat, also known as "Basket" Cassette

Function & Application:

Utilized in wafer production and semiconductor manufacturing cleaning processes. It serves as a carrier for silicon wafers during acid cleaning and ultrasonic cleaning steps, coming into direct contact with monocrystalline silicon wafers. This is a low-temperature process.

Performance Requirements:

Corrosion resistance and low impurity content.

-

No.5177 Qianghua West Road, Dongqian Street, Nanxun District, Huzhou City, Zhejiang Province

-

+86-572-3032373

+86-572-3033016

The wafer carrier quartz boat, also known as a “basket” cassette, is engineered for secure wafer handling during semiconductor cleaning processes. Made from high-purity fused quartz, it ensures excellent chemical resistance and minimal impurity levels, making it suitable for direct contact with monocrystalline silicon wafers. Optimized for low-temperature acid and ultrasonic cleaning, this precision component supports stable wafer alignment and reduces contamination risks. Ideal for cleanroom environments in semiconductor fabrication and research applications.

How Wafer Carrier Quartz Boat Design Affects Wafer Uniformity and Yield

Wafer carrier quartz boats are essential components in semiconductor manufacturing, serving as the high-purity holders that transport silicon wafers through high-temperature processes such as diffusion, oxidation, and chemical vapor deposition (CVD). While their primary role is seemingly straightforward—to securely hold wafers—their design intricacies significantly impact wafer uniformity and overall production yield. Understanding these design factors is critical for fabs aiming to optimize process consistency and minimize defects.

The Importance of Quartz Boat Design in Semiconductor Fabrication

Quartz, known for its excellent thermal stability, chemical inertness, and low impurity content, is the material of choice for these boats. However, not all quartz boats are created equal. Slight variations in design, such as slot geometry, material quality, and dimensional tolerances, can influence how evenly heat and process gases interact with each wafer. This interaction directly affects the uniformity of wafer processing and thus the yield — the proportion of wafers meeting quality standards after fabrication.

Key Design Elements Influencing Wafer Uniformity

1. Slot Geometry and Wafer Spacing

The quartz boat’s slots, where wafers are inserted vertically, must maintain precise spacing. Too tight a fit can cause mechanical stress and restrict gas flow, leading to uneven chemical exposure. Too loose, and wafers may shift or tilt, risking physical damage or non-uniform treatment.

Optimized slot width and shape ensure that wafers are held firmly while maximizing the exposure of all wafer surfaces to process gases. Uniform gas flow reduces boundary layer variations and promotes consistent diffusion and deposition rates across wafers.

2. Material Purity and Surface Finish

High-purity synthetic quartz minimizes contamination risks. Impurities in the quartz can outgas or interact with process chemicals, introducing particles or defects onto the wafer surfaces.

Additionally, the surface finish inside the slots affects particle generation and gas dynamics. A smooth, polished interior reduces micro-particles and prevents unwanted chemical reactions, preserving wafer integrity and cleanliness.

3. Dimensional Stability and Thermal Expansion

During high-temperature cycles, quartz boats expand and contract. The design must accommodate thermal expansion to avoid warping or slot deformation, which can misalign wafers and disrupt uniform heating.

Manufacturers often select quartz grades with low thermal expansion coefficients and engineer boat dimensions to maintain slot spacing throughout the temperature range. This stability ensures consistent wafer positioning and process uniformity.

How Design Impacts Yield

Yield in semiconductor fabs is a key metric directly affected by defects and process inconsistencies. Poor quartz boat design can cause:

- Non-uniform layer thickness: Uneven heat or gas flow leads to inconsistent oxide or nitride layer growth, affecting device performance.

- Particle contamination: Surface roughness or quartz impurities generate particles that cause defects.

- Mechanical wafer damage: Misaligned or unstable wafers can crack or chip during handling or processing.

By contrast, well-designed quartz boats promote uniform thermal and chemical environments, reducing defect density and improving overall yield.

Advanced Design Approaches for Enhanced Performance

Modern quartz boat designs leverage computational fluid dynamics (CFD) simulations and thermal modeling to optimize slot geometry and gas flow paths. Customized boat shapes may accommodate specific wafer sizes or multi-wafer stacks, further enhancing throughput without sacrificing uniformity.

Some fabs also apply surface treatments or coatings to quartz boats to improve durability and reduce particle generation, balancing longevity with process cleanliness.

The design of wafer carrier quartz boats plays a pivotal role in ensuring wafer uniformity and maximizing semiconductor fabrication yield. From precise slot geometry to high-purity materials and thermal stability, each design aspect influences how wafers interact with high-temperature processes. Semiconductor fabs focusing on optimizing quartz boat design stand to gain significant improvements in product quality and manufacturing efficiency.