NEWS DETAIL

Thermal Shock as a Primary Cause of Quartz Cracking

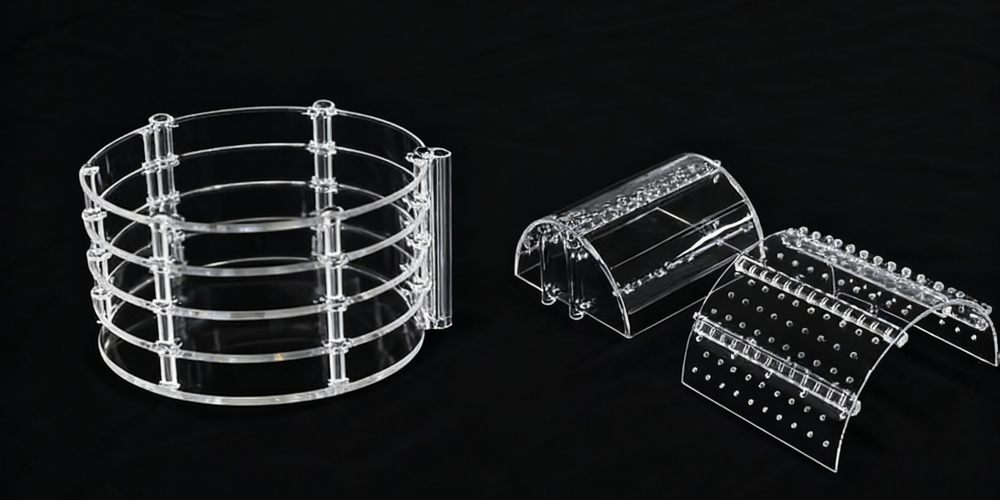

Industrial quartz, especially fused or synthetic quartz, is highly valued for its thermal stability and optical clarity. However, even this resilient material is not immune to thermal shock, a primary culprit behind cracking. Thermal shock occurs when quartz experiences rapid temperature changes, creating differential expansion within the material.

In practice, industrial applications such as quartz tubes in semiconductor furnaces or high-temperature lamps often expose quartz to sudden heating or cooling cycles. The resulting internal stress can exceed the fracture strength of the quartz, forming microcracks that propagate over time. Unlike metallic materials, quartz lacks plasticity, meaning it cannot deform to relieve stress.

Design strategies, such as gradual temperature ramp-up and ramp-down or incorporating stress-relief annealing, can significantly reduce thermal shock risk. Understanding the specific heat tolerance and thermal expansion coefficient of your quartz grade is critical for reliable performance.

How Impurities and Trace Elements Trigger Devitrification

While thermal shock primarily leads to cracking, devitrification—the transformation of amorphous quartz into crystalline forms—can weaken the material and compromise optical or mechanical properties. Impurities, including alkali metals or residual oxides, act as nucleation sites for crystal growth.

Trace elements introduced during synthetic quartz production or from raw silica feedstock can accelerate devitrification at elevated temperatures. This process often begins at microscopic inclusions or surface irregularities, gradually reducing transparency and increasing brittleness.

Industrial engineers must therefore carefully select high-purity quartz for applications in optical devices, photolithography, or chemical processing, where devitrification could lead to catastrophic failures.

Thermal History: Why Improper Annealing Weakens Quartz

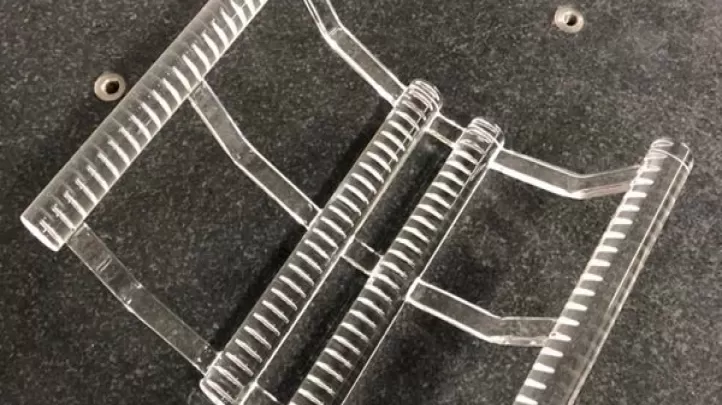

Annealing is a critical step in synthetic quartz manufacturing, relieving internal stresses induced during melting and shaping. Improper or incomplete annealing leaves residual stress pockets within the quartz structure, making it vulnerable to cracking even under moderate thermal or mechanical loads.

For example, quartz plates used in semiconductor equipment that skip proper annealing can develop invisible microfractures. Over time, these microfractures grow under operational stress, leading to sudden failure. Ensuring a controlled cooling profile and sufficient annealing time is essential for producing robust industrial quartz components.

Understanding the relationship between annealing temperature, time, and quartz thickness allows manufacturers to optimize structural integrity and extend service life.

What Devitrification Really Means in Industrial Quartz

Many engineers misunderstand devitrification as mere discoloration. In reality, devitrification involves the formation of crystalline silica phases within the previously amorphous quartz matrix. This crystalline growth alters mechanical, thermal, and optical properties, often creating stress concentrations that can lead to cracking.

Devitrification usually initiates at contaminated areas or surfaces exposed to high temperatures, and progresses inward. This is particularly relevant for quartz tubes in high-temperature chemical processing or furnace components, where maintaining amorphous structure is crucial for transparency and thermal uniformity.

Monitoring and controlling exposure temperatures and chemical environments can mitigate devitrification risks, preserving material performance over long operational periods.

Chemical Atmospheres That Accelerate Devitrification

Beyond thermal factors, chemical environments play a significant role in accelerating devitrification. Quartz exposed to alkali vapors, reactive gases, or humid atmospheres can experience localized crystallization at much lower temperatures than in neutral conditions.

For instance, in semiconductor fabrication, quartz components encounter corrosive fluorine or chlorine gases. These reactive chemicals not only etch the surface but also catalyze devitrification, compromising both mechanical strength and optical clarity.

Proper material selection, protective coatings, and controlled gas flow are essential strategies to prevent chemical-induced devitrification. Additionally, regular inspection for early signs—such as slight cloudiness or surface roughening—helps detect issues before irreversible damage occurs.